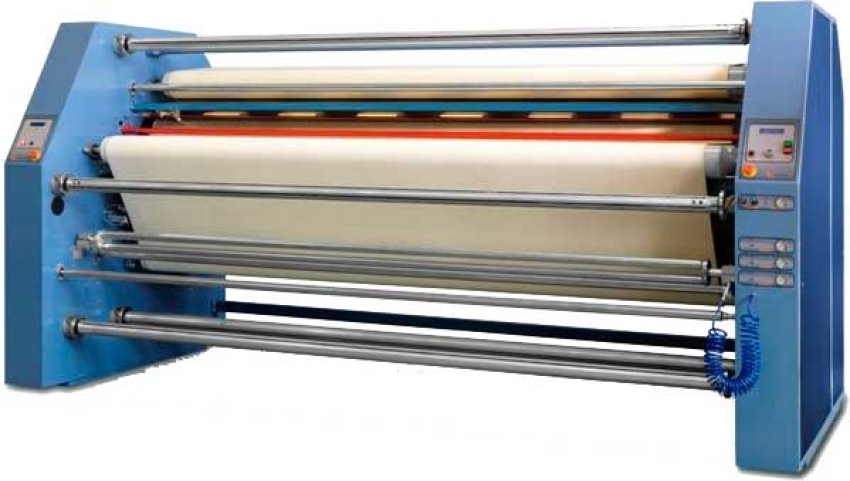

GFO 67 CALENDER

Continuous printing width of 160 cm

Rotary calender for continuous sublimation of transfer paper to synthetic, knitted or non-woven polyester fabrics such as nylon and acrylic. In case of direct printing on the polyester fabric with digital printers, the grille can be used to fix the color pigments in a perfect and economical way.

Practical and precise, the GFO 67 has 2 proportional electronic thermostats, the first for oil control and the other for the outside of the cylinder.

PRODUCTION SET UP:

The three expansion shafts allow the operator to take and position the transfer paper, the printing material and, if necessary, the protective paper. By using gravity to load the machine in a straight and uniform manner, the transfer paper is positioned directly above the input of the printing rollers; tension can be adjusted via a pneumatic clutch control device: the material is tensioned and through an «s» which tends the product more; the material moves over an expansion roller which guarantees a straight path towards the press entrance.

WRAPPING OF TRANSFER PAPER AND PRINTED FABRIC:

An important feature is the immediate separation of paper and fabric at the exit of the printing phase and their transport to the back of the machine where they ensure easy access to the respective reels. The pneumatic spool holder rods and supports have been designed to allow the operator to remove the finished spools and reposition the rod in one move. The pneumatic clutch and the electronic speed control device allow a simple adjustment of the winding tension.

Caracteristic(s) :

- Felt size: 168 cm

- Useful width: 160 cm

- Power: 20 Kw

- Average consumption: 10 kW/H

- Weight: 1 190 kg

- Dimensions (W x H x D): 253 x 158 x 160 cm

- Production 1.07 ML/min

- Security bar and reverse control

- Cylinder: Ø 33 cm

- Adjustable tape tension

- Brushless motor

- Electropneumatic dynamic tape control

- Automatic timer cylinder cooling

- Ultra-light air expansion shafts for unwinders and rewinders

- Optional loading table

- Variable speed control

- The machine must be connected to compressed air

- Useful width: 160 cm

- Power: 20 Kw

- Average consumption: 10 kW/H

- Weight: 1 190 kg

- Dimensions (W x H x D): 253 x 158 x 160 cm

- Production 1.07 ML/min

- Security bar and reverse control

- Cylinder: Ø 33 cm

- Adjustable tape tension

- Brushless motor

- Electropneumatic dynamic tape control

- Automatic timer cylinder cooling

- Ultra-light air expansion shafts for unwinders and rewinders

- Optional loading table

- Variable speed control

- The machine must be connected to compressed air